|

ELECTROFORMING |

Microfiltration

Accurate particle selection is possible by using

precisely patterned holes in a metal membrane. Metal filters are well suited

for being used with organic chemicals and at high temperature.

Laser projection marking

Laser marking and trimming use micromachined masks

for projecting the laser radiation through a reduction optics. If details

below 10 micron are to be reproduced in the marking, a precision patterned

mask is required. Such mask should preferably lay on no substrate, since

this could be damaged by the laser radiation (typically high energy pulses

from a Neodimium-YAG or an Excimer laser). A self sustaining electroformed

mask can easily do the job.

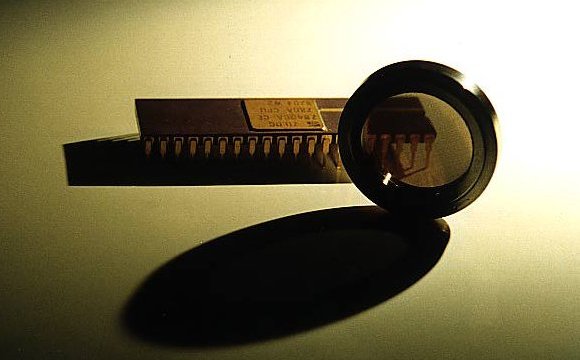

Radiation broadband attenuation

Neutral density filters, with really broad and flat

band, can be fabricated for non imaging applications. The transmission

depends on the empty/full ratio in the metal layer. Variable transmission

devices can be obtained by cascading two attenuators and rotating one with

respect to the other. A typical attenuator for radiation measurement exhibits

a flat response from deep UV to far IR, through VIS and near-IR. One such

attenuator is shown in the first photograph below, where an integrated

circuit is observed partly directly and partly through the filter (10%

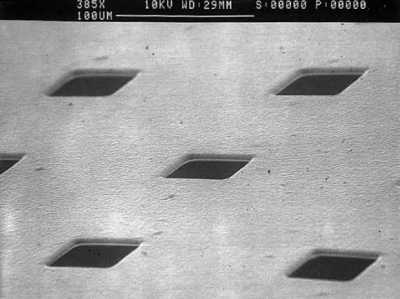

transmission). The next photograph shows the filters in reflected light.

The last two SEM photographs show details of the filters.

|

|